Understanding Rolling Mill Gearboxes: The Power Behind Steel Production

By Sajjanson Engineers | Steel Solutions Blog

In the world of steel manufacturing, efficiency, reliability, and power are everything. At the heart of it all lies a crucial component: the rolling mill gearbox. Whether you're producing TMT bars, structural steel, or flat products, your rolling mill’s performance heavily depends on the gearbox driving it.

At Sajjanson Engineers, we understand the demands of modern steel mills, and that’s why we design and supply high-performance rolling mill gearboxes built to deliver long-term value and efficiency.

Let’s take a closer look at what makes these gearboxes so essential — and how choosing the right one can significantly improve your plant’s productivity.

🔧 What Is a Rolling Mill Gearbox?

A rolling mill gearbox is more than just a mechanical transmission system. It plays a vital role in transmitting power and torque from the motor to the rollers that shape and compress steel. It also ensures the right speed reduction and torque multiplication needed for various stages of the rolling process.

Given the intense load and harsh working environment in a steel mill, these gearboxes must be rugged, reliable, and precisely engineered.

⚙️ Key Functions of Rolling Mill Gearboxes

Rolling mill gearboxes are expected to:

-

Transmit high torque under continuous loads

-

Reduce motor speed to match rolling speed requirements

-

Maintain alignment and mechanical integrity under stress

-

Ensure smooth and efficient power delivery

-

Operate reliably in high-temperature, high-pressure environments

At Sajjanson Engineers, every gearbox is designed with these performance factors in mind.

🛠️ Types of Rolling Mill Gearboxes

Depending on your mill layout, production requirements, and load conditions, you may need different types of gearboxes. Here are the most common ones we offer:

1. Helical Gearboxes

Known for their quiet operation and high efficiency, helical gearboxes are ideal for continuous rolling applications. Their angled teeth provide smooth meshing and better load distribution.

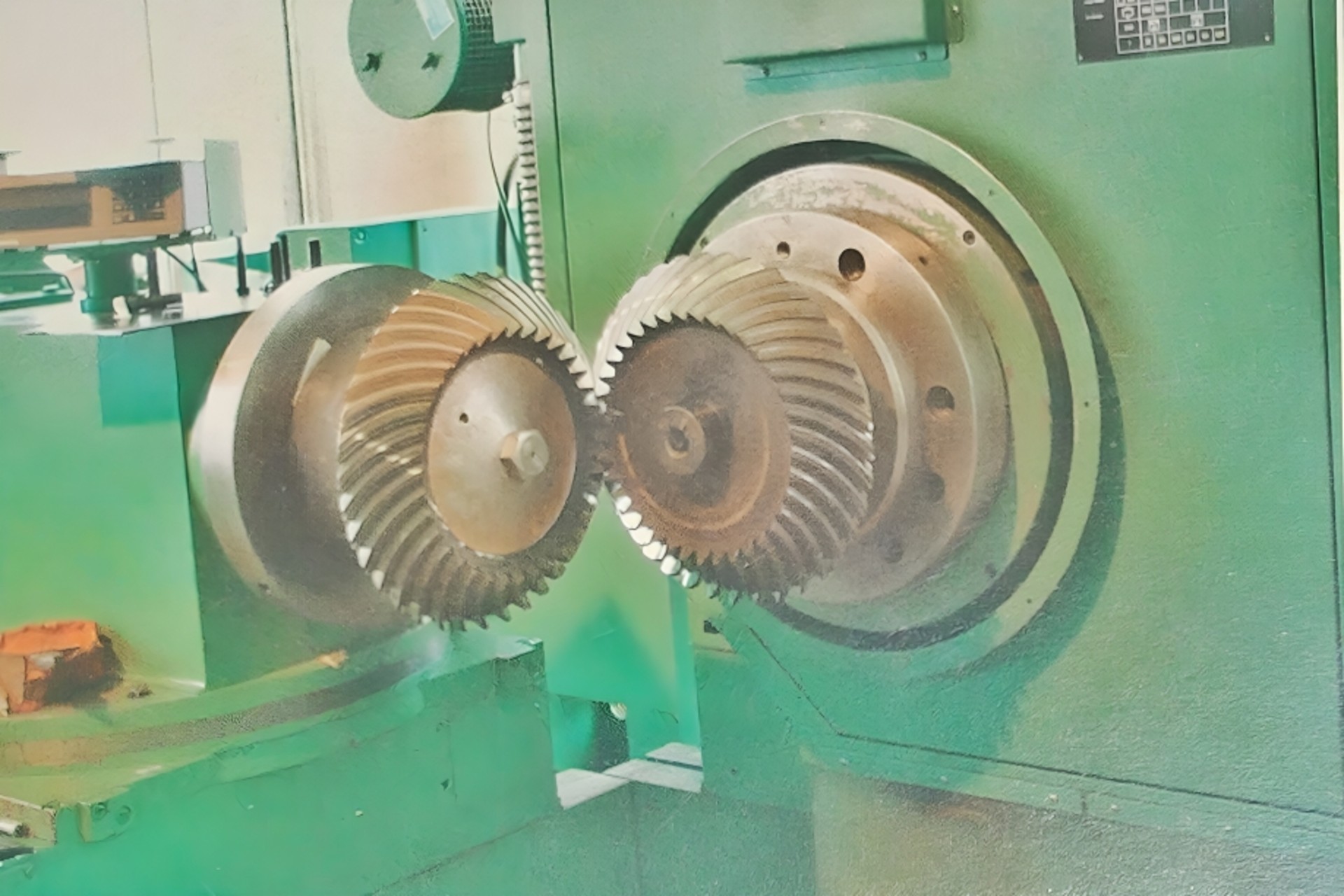

2. Bevel Gearboxes

Perfect for mills where the input and output shafts aren’t parallel. Bevel gearboxes are compact, efficient, and offer precise angular motion transmission.

3. Planetary Gearboxes

Designed for high torque and low-speed applications, planetary gearboxes offer compact size and balanced power distribution — ideal for heavy-duty rolling operations.

4. Worm Gearboxes

These are used in mills where high speed and low torque are required. Worm gearboxes are self-locking and cost-effective for lighter applications.

🧰 Best Practices for Gearbox Maintenance

To keep your rolling mill gearboxes running smoothly and avoid costly downtimes, we recommend the following:

-

Routine Inspections

Regular checks help identify wear, misalignment, or unusual noise early on. -

Proper Lubrication

Always use the right lubricant for your gearbox type and operating conditions. Lubrication reduces friction, heat, and wear. -

Temperature Monitoring

A sudden rise in temperature could signal a problem — like a lubrication issue or internal damage. -

Alignment Checks

Misalignment can cause vibration, gear wear, and even shaft failure. Keep your systems properly aligned to extend life and performance.

✅ Why Choose Sajjanson Engineers?

We’re not just gearbox suppliers — we’re steel solution partners. Our gearboxes are:

-

Engineered for Indian and international mill conditions

-

Built using premium materials and modern design standards

-

Supported by in-depth technical expertise and after-sales support

-

Customizable for your specific rolling mill setup

Whether you need a high-torque gearbox for billet rolling or a compact solution for your bar mill, Sajjanson Engineers has you covered.

🏁 Final Thoughts

The gearbox might be hidden under steel and structure, but its impact on your mill’s productivity is massive. Investing in the right rolling mill gearbox — and maintaining it well — can dramatically improve your output, energy efficiency, and equipment life.

Looking for a custom gearbox or upgrading your current system?

📞 Contact us today to explore the best solution for your mill.

📍 Blog by Sajjanson Engineers – Your Partner in Reliable Rolling Mill Solutions

#GearboxSolutions #RollingMillTechnology #SteelPlantEngineering #SajjansonEngineers

Let me know if you'd like to include photos, animations, case studies, or downloadable brochures with this blog!